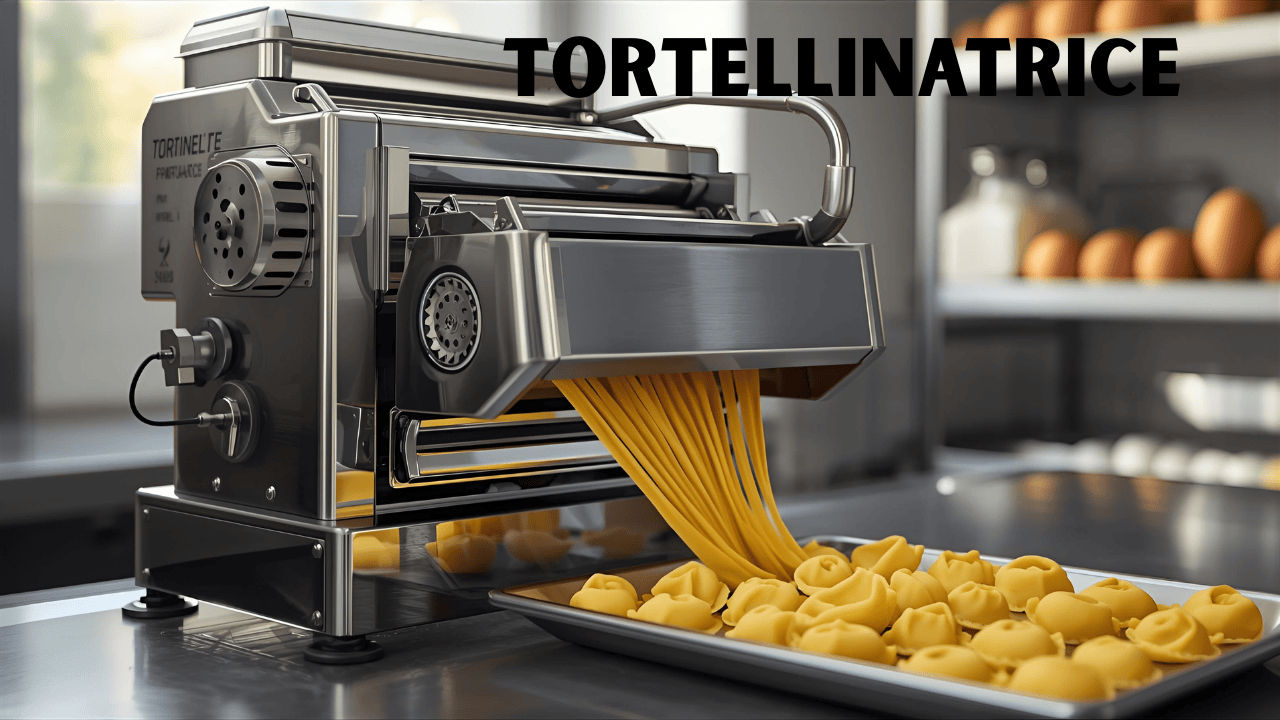

Tortellinatrice: Tradition, Technology

Italian cuisine is celebrated across the world for its deep connection to tradition, craftsmanship, and culture. Among its countless treasures, tortellini stand out as one of the most iconic types of pasta. These small, ring-shaped delights are filled with rich ingredients and represent centuries of culinary artistry rooted in Emilia-Romagna. While tortellini are often made by hand, modern technology has introduced machines that replicate this labor-intensive process with precision and efficiency. One such innovation is the tortellinatrice—a specialized machine designed to produce tortellini at scale while preserving the essence of their artisanal origins.

In this article, we will explore what a tortellinatrice is, its role in the food industry, how it bridges tradition with modernity, and why it has become indispensable in both professional kitchens and pasta production facilities.

What is a Tortellinatrice?

The word tortellinatrice comes from Italian, directly meaning “tortellini maker.” It refers to an industrial or semi-industrial machine specifically designed to shape tortellini automatically. Unlike general pasta machines that can create multiple types of pasta (like spaghetti or ravioli), a tortellinatrice is tailored for the intricate folds and curves of tortellini.

Its primary function is to replicate the manual steps of preparing tortellini:

-

Rolling out pasta dough into thin sheets.

-

Cutting dough into small squares or circles.

-

Placing the filling (usually meat, cheese, or vegetables).

-

Folding the pasta and sealing it into the traditional ring-shaped form.

With advanced engineering, a tortellinatrice ensures uniformity, speed, and hygiene, making it possible to produce thousands of tortellini per hour—something unimaginable through manual labor alone.

The Cultural Importance of Tortellini

To fully appreciate the significance of the tortellinatrice, one must understand the symbolic weight of tortellini in Italian culture. Legend has it that tortellini were inspired by the navel of Venus, the goddess of love, when a curious innkeeper in Bologna tried to capture her beauty in pasta form. Whether fact or myth, this tale has immortalized tortellini as a dish tied to romance and artistry.

Traditionally, families in Emilia-Romagna gather during holidays to prepare tortellini by hand, filling them with a mixture of pork loin, prosciutto, Parmigiano Reggiano, nutmeg, and egg. The pasta is then served in a rich broth, a dish known as tortellini in brodo.

The tortellinatrice does not replace this cherished ritual but rather complements it in a modern setting, ensuring the culinary tradition thrives beyond the family kitchen, reaching restaurants, supermarkets, and international markets.

Evolution of Pasta-Making Machines

Before the invention of the tortellinatrice, pasta-making machines primarily focused on simpler shapes like spaghetti, penne, or lasagna sheets. These required extrusion or cutting, which were easier to automate. Tortellini, however, posed a unique challenge because of their delicate folding process.

The first generation of tortellinatrici emerged in the mid-20th century as food industries sought to meet rising demand for packaged pasta. These early machines were bulky, required constant supervision, and often lacked the finesse needed to perfectly seal tortellini. Over time, innovations in robotics, food-safe materials, and precision engineering allowed for the development of more sophisticated machines capable of mimicking hand-folding techniques with remarkable accuracy.

Today, modern tortellinatrici are equipped with programmable controls, stainless steel components, and adjustable settings to produce tortellini of various sizes and fillings.

How a Tortellinatrice Works

A tortellinatrice typically functions through a series of interconnected steps:

-

Dough Preparation: Sheets of pasta dough are fed into the machine at a controlled thickness.

-

Filling Deposition: The machine precisely injects the filling into each cut section of the dough.

-

Cutting and Folding: Using mechanical arms or rollers, the dough is cut and folded around the filling, shaping it into the iconic ring form.

-

Sealing: Pressure and design molds ensure that the pasta edges are sealed tightly to prevent leaks during cooking.

-

Output: Finished tortellini are collected on conveyor belts, ready for packaging, freezing, or immediate cooking.

The accuracy of the tortellinatrice ensures that each tortellino is consistent in weight, shape, and texture, a key factor for restaurants and manufacturers that rely on uniformity.

Benefits of Using a Tortellinatrice

1. Efficiency and Productivity

While a skilled artisan can produce a few hundred tortellini in an hour, a tortellinatrice can produce thousands, making it ideal for large-scale food businesses.

2. Consistency

Every tortellino is identical in size and shape, which enhances presentation and portion control in commercial kitchens.

3. Cost Savings

By automating labor, businesses reduce reliance on manual work while meeting high-volume demand.

4. Hygiene and Safety

Made from food-grade stainless steel, tortellinatrici maintain sanitary standards that are essential for packaged food production.

5. Versatility

Modern machines can be adjusted to create variations in size, dough thickness, and filling quantity, catering to different culinary needs.

Types of Tortellinatrici

Not all tortellini-making machines are the same. Depending on the production scale, they can be categorized as:

-

Artisanal Tortellinatrici: Smaller machines designed for restaurants, bakeries, or gourmet shops that want to maintain a handcrafted touch while boosting productivity.

-

Industrial Tortellinatrici: Large, fully automated systems capable of producing thousands of tortellini per hour, suitable for factories and major pasta brands.

-

Semi-Automatic Tortellinatrici: These combine manual and mechanical processes, giving operators more control while increasing efficiency compared to hand-making.

Tortellinatrice and Culinary Innovation

While tradition emphasizes tortellini filled with pork and cheese, modern culinary experimentation has expanded the horizons. With the help of a tortellinatrice, chefs and food companies now produce tortellini with vegetarian fillings (spinach and ricotta, pumpkin, mushrooms), seafood fillings, or even dessert-style versions with chocolate or sweet ricotta.

The machine’s adaptability allows chefs to scale up creative recipes while keeping quality intact. This flexibility is crucial in a global market where consumer preferences vary widely.

Challenges of Using a Tortellinatrice

Despite its advantages, the tortellinatrice is not without limitations:

-

Initial Cost: High-quality machines require significant investment, making them less accessible to small family-run businesses.

-

Skill Requirement: Operators must be trained to adjust settings, maintain the machine, and troubleshoot issues.

-

Artisanal Value: Some purists argue that no machine can fully replicate the touch and intuition of a skilled pasta maker.

However, these challenges are often outweighed by the benefits in contexts where large-scale production is necessary.

Tortellinatrice and the Global Pasta Market

The global pasta industry has seen exponential growth, with demand spreading far beyond Italy. In countries like the United States, Germany, and Japan, tortellini are enjoyed as both fresh and packaged products. The tortellinatrice plays a critical role in making this globalization possible.

Without machines, it would be impossible to meet international demand while keeping costs manageable. Large-scale brands rely heavily on industrial tortellinatrici, while smaller shops use compact models to offer authentic, freshly made pasta to their customers.

The Future of Tortellinatrici

As technology advances, the future of tortellinatrici looks promising. Trends shaping the industry include:

-

Smart Automation: Machines with AI and sensors that can detect dough texture, adjust filling levels, and ensure perfect sealing without human intervention.

-

Sustainability: Eco-friendly designs that minimize energy consumption and food waste.

-

Customization: Machines that allow real-time recipe adjustments for unique fillings and dough types.

-

Integration with Robotics: Collaborative robots (cobots) working alongside chefs to combine automation with artistry.

The fusion of tradition and innovation ensures that tortellini will continue to be celebrated around the world, with tortellinatrici playing a central role in their journey.

Conclusion

The tortellinatrice is more than just a machine—it represents the blending of heritage and modernity. While tortellini were once the exclusive product of nimble hands in Italian kitchens, today they can be enjoyed globally thanks to the precision and efficiency of these specialized machines.

By preserving the authentic form and flavor of tortellini while making them accessible on a mass scale, the tortellinatrice ensures that this culinary treasure continues to thrive for future generations.

In the end, whether shaped by hand or by machine, tortellini embody the same essence: a symbol of Italian craftsmanship, creativity, and love for food. The tortellinatrice simply allows that tradition to flourish in a modern world.

Post Comment